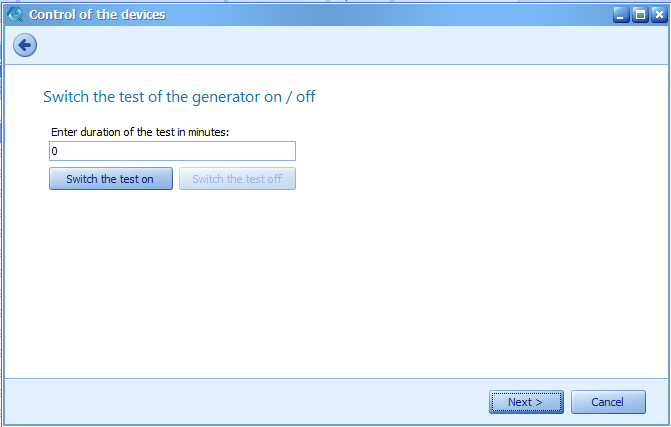

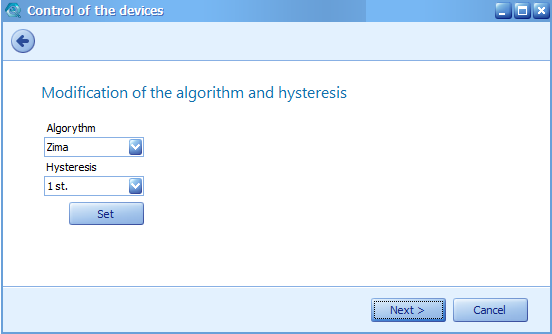

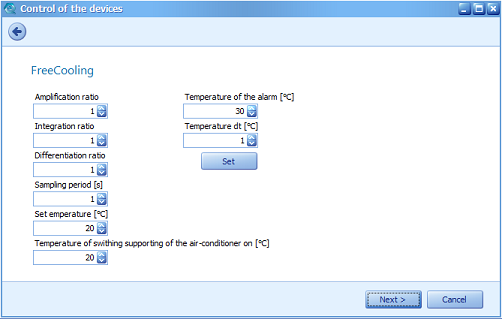

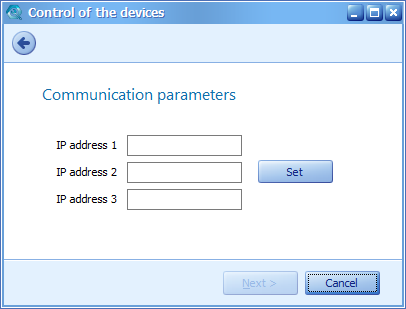

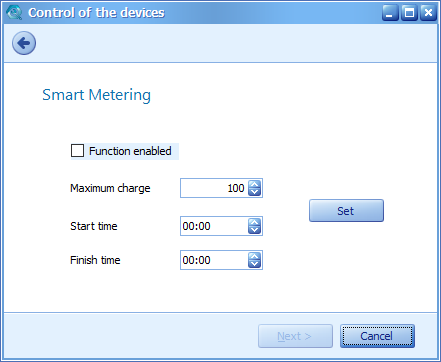

In the consecutive window it is necessary to enter appropriate values of parameters, click "Set" and approve the command. Click "Forward >" to go further on. After confirmation the request will be sent to the system.

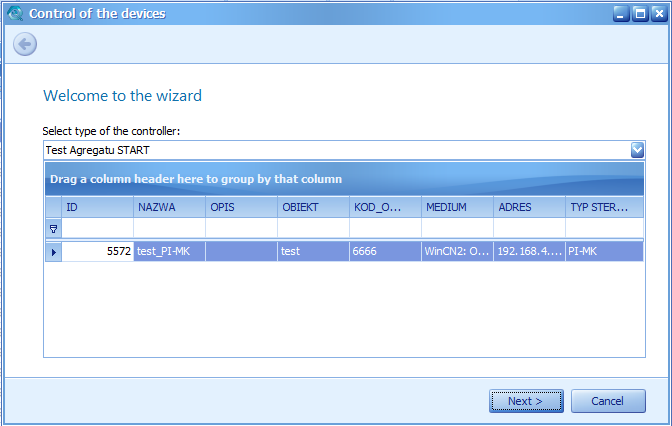

Test of the Generator – this function enables to verify if operation of the generator is correct.

Modification of the Hysteresis Algorithm – enables to modify parameters of the algorithm and hysteresis in the controller.

Freecooling – enables to modify parameters of the Freecooling.

The following parameters can be modified remotely:

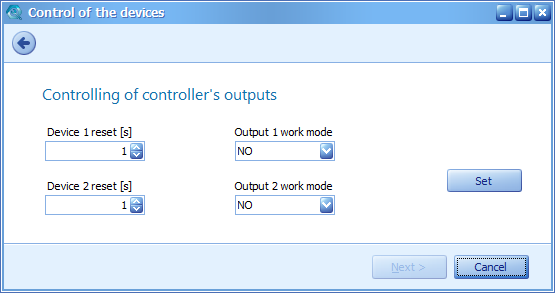

Control of the outputs – control function enabling to set values at outputs of the controller; this function enables remote reset of the connected device.

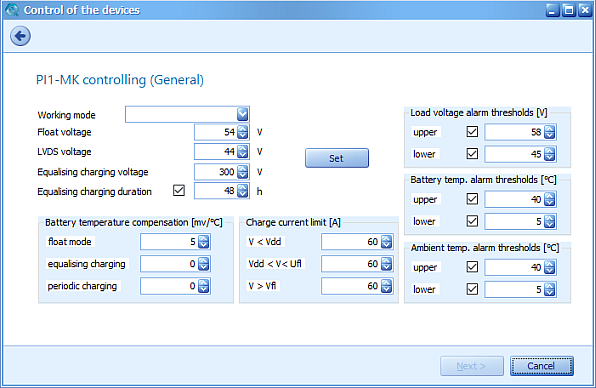

PI1-MK control (General) - control function enabling to set alarm thresholds in the PI1 controller, and such parameters as: Operation mode, or time of automatic charging.

The following parameters can be modified remotely:

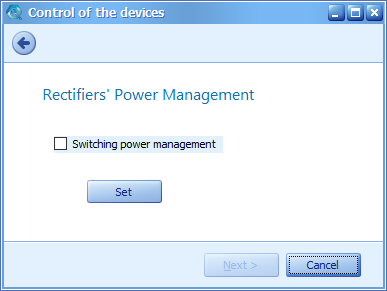

Rectifiers power management – separate control function enabling to switch on and off management of the rectifiers power in the PI1 controllers.

Smart Metering – battery control function. The control refers to PI1 controller, communication with application of MK protocol.

The following parameters may be modified remotely:

STB test – STB Battery Testing System is meant for automatic and maintenance-free diagnosis of the batteries during their operation. The system allows assessing key parameters of the battery, which condition energetic security of the entire site. STB applies the only one method that is known to verify real capacity of the battery. It is the method of direct measurement of energy consumed by the load during deep discharge. This process is performed automatically under supervision of the Pi1 controller in cooperation of measurement and executive elements. Reliable information regarding status of the battery allows undertaking optimal actions in correct time and at minimal cost in order to ensure continuity of power supply to the loads. Basic users may apply the buttons enabling to start and stop the test manually. The following information is recorder in the log:

Basic STB – basic user is authorised to modify a few parameters of the STB’s operation. During presentation of start time of the first test it is obligatory to verify if this time was preset. If it was not, the user should be aware about this fact. If during setting the parameters the user does not mark, that he is willing to set this time, the parameter will not be sent to the controller. Other option is to set cycle of days. Planned discharge time is not sent directly in [h], but in a form of index from the table of available values. Advanced STB – except for previous parameters, advanced users are also able to set the following ones:

SNOB – Battery cells supervision system. It is meant for setting operation parameters of the system. Alarm thresholds of battery cell voltage are presented in [V], but during transmission to and from the controller the values are transferred in [mV]. Deviation is always presented as percentage value. Prior to sending, all the parameters are verified whether they do not exceed permissible range of values. The panel enables to switch off alarm thresholds. Management of the socket – function enabling to switch on or off individual sockets of the particular site. In order to perform this, it is necessary to select status of the socket, mark particular verses of the table and click "Set selected ones" button. |